After the pre-drying stage, pasta enters into the dryer stage , which has either three or six tiers system. These tiers are physically separated from one another and house the technological core of the humidity Active System. Pasta passes through accelerated drying and stabilisation zones in which temperature and humidity parameters are programmed in order to achieve perfect drying.

Continuous Dryer Machine

Spreader with sticks up to 1500mm of length, with a device for collecting the cutting scraps, mincing them and returning them to the press unit again. Continuous dryer featuring mats in thermo-resistant, polyester mesh made up of two technological areas equipped with independent climate control probes; predrying, drying and stabilization areas. The panelling that can be fully opened all along the machine perimeter.

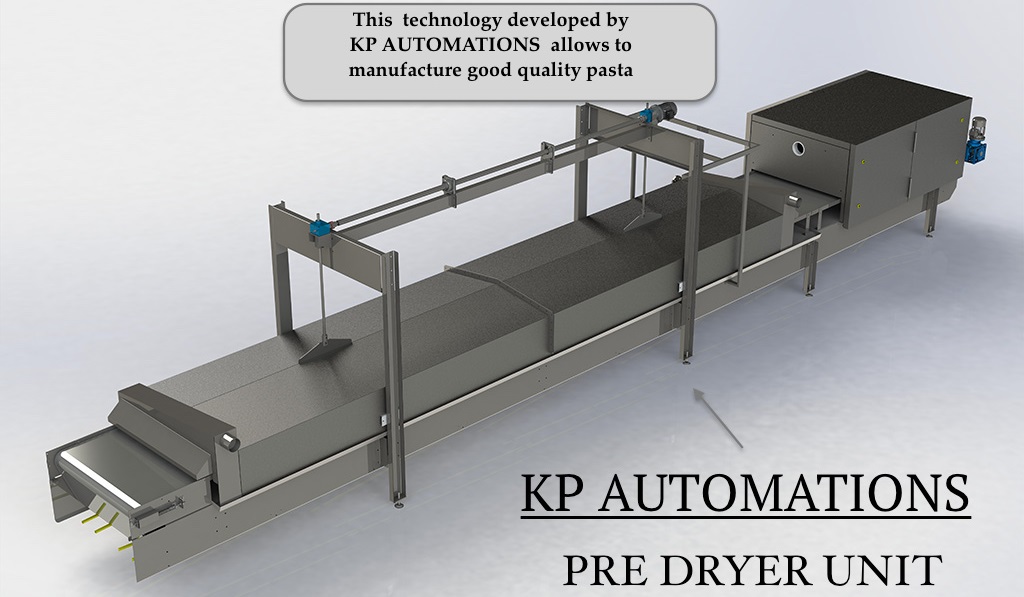

Pre-dryer Machine

This is the main stage for drying. Pasta is surface-dried with very hot air flows before entering the final dryer for temperature control. Pre-dryer by five vibrating tiers: stainless steel structure, looms and panelling that can be easily opened and cleaned. Heating system by finned heat exchangers running either by hot or overheated water, served by axial electro-ventilators suitable for treatment temperature up to 80°C.

HAS Dryer Machine

Drying process is enhanced by humidity - active climatic zones. The structure is made up of physically separate process tiers for maximum humidity and temperature control at every point in the drying unit. A highly effective recirculation of air system is provided in the dryer. The system is designed so that the materials at the top and the bottom dry simultaneously.

Cooling Machine

This machine is equipped with automatic ventilation units with cold water heat exchangers that bring the pasta to an ideal temperature before the packaging stage or ready for the final product stage. Cooler served by high-performance axial fans that draw air from the ambient or - upon demand - through freon evaporators or glycol water running exchangers. Transport of the product is effected on polyester mat driven by variable speed, independent gear motor.

Conveyor Machine

Its is for the final packaging stage when the pasta come into the normal temp for packaging on the conveyor. The conveyor belt is positioned close to the extrusion cylinder of the pasta machine, and the spaghetti or any other long pasta is transported at the same extrusion speed of the machine towards the cutting unit where it is then cut. Thanks to the potentiometer it is possible to choose the cutting time and the speed of the conveyor belt in order to adapt it to the extrusion speed of the press.